Oil platforms are exposed to a major fire risk. So meeting preventive fire safety measures is essential. The optimal preventive measure? A high-temperature insulation system. Because a prevented fire does not need to be extinguished.

Fire and explosion risks on oil platforms

Fire protection on oil platforms should be a top priority, as both the equipment used and the plant environment are highly susceptible to fire. Highly flammable materials, liquids and gases, coupled with high ambient and surface temperatures of the machinery result in a potentially fatal fire risk.

On the one hand, the use of electrical equipment and machinery can lead to failure in the form of short circuits and resulting machine fires. On the other hand, continuous running at full speed can lead to overheating, which can also cause a fire.

In the worst case, wear and tear on the machinery can lead to leaks. This can cause operating fluids, oils, or gases to escape – all of them highly flammable. If these come into contact with the hot surfaces in the engine compartment, a fire, or even an explosion can quickly occur.

Fires on an oil platform spread quickly and pose a major risk to the safety of people and machinery.

When a fire breaks out on an oil platform

A fire on an oil platform can quickly escalate. Due to the highly flammable, even explosive, liquids and gases, extreme caution is required. Fires and explosions at sea are difficult to extinguish, and escape routes are not easily accessible.

If the underwater pipelines of the platform are damaged, oil spills will occur, which can destroy the nature and habitat of many animals for a long time. In addition, such a fire may cause damage to the oil platform, resulting in interruption of oil production and economic losses.

It is therefore essential to preventively protect the oil platform in the best possible way and mitigate the risk of fire.

What fire safety standards are oil platforms subject to?

Oil platforms are subject to the SOLAS standard. In 1913, a convention was adopted regarding safety and protection at sea. This decision was related to the sinking of the RMS Titanic and the tragedy that accompanied this shipwreck. New standards for the safety of human life at sea had to be created.

A continuation of this convention is the “International Convention for the Safety of Life at Sea”, which is a UN convention held in 1974, in which a new set of rules for the safety of the navy was laid down. The safety standards listed here include factors such as the construction, equipment, and operation of ships. The SOLAS standard applies in international waters and to all ships with a gross tonnage (GT) over 500, as well as passenger ships with over 36 passengers.

Fire safety regulations are also specified and prescribed in the document. These were revised again in July 2002 and, in addition to more stringent requirements for the components and materials used, also stipulate that no surface of any component used may exceed the 220 °C mark.

Failure to comply with the SOLAS criteria risks not only the license, but also the safety of the crew and passengers on board. The temperature mark of 220 °C must be maintained at all costs in order to minimize the risk of fire and maximize the safety potential.

The oil spill: Deepwater Horizon

A devastating fire due to lack of maintenance occurred on the Deepwater Horizon oil rig on April 20, 2010.

Excessive pressure caused oil and gas to escape uncontrollably, and the platform's warning systems did not work. On contact with hot surfaces, an explosion occurred, the platform caught fire and sank two days later. Eleven people died, and it is estimated that 800 million liters of oil spilled into the Gulf of Mexico.

To prevent such a disaster in the future, Transocean's rigs were fitted with high-temperature insulation after the incident.

There are around 225 drilling rigs operating worldwide, all of which require suitable insulation protection to ensure maximum occupational safety.

What is a high-temperature insulation?

The greatest danger on an oil platform is the high temperatures. It is not unusual for surface temperatures of up to 1,000 °C to prevail in the engine compartment. It is therefore necessary to reduce the temperatures. After all, this is also required by the SOLAS guidelines.

This is best achieved with suitable high-temperature insulation. A solid and well-fitted insulation helps with targeted temperature control and thus allows effective fire protection. This is because fire protection is increased at low temperatures. In addition, a low temperature contributes to the efficiency and safety of the machinery.

The SOLAS standard requires temperatures below 220 °C, as many operating materials ignite at only 250 °C. Our tmax metallic insulation accomplishes that and more. It is able to reduce surface temperatures to as low as 60 °C, since gases ignite at temperatures as low as 80 °C. This ensures optimum fire protection for your machines.

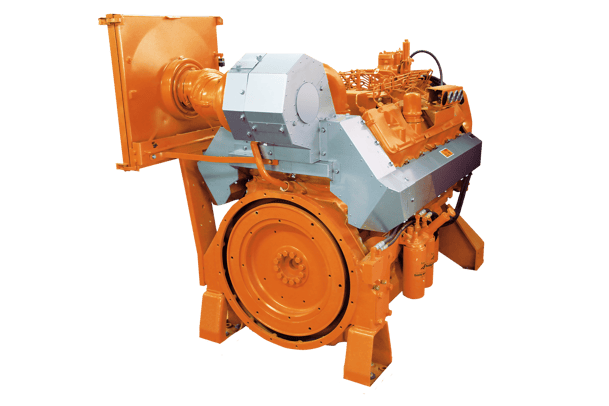

Picture: A metallic high temperature insulation by tmax on the engine of an oil platform.

Our engineering know-how, combined with our specialization in developing tailor-made insulation solutions based on customer requirements, makes us a pioneer in temperature management through insulation protection. Depending on the requirements, there is a choice between metallic insulation or textile insulation.

We have decades of expertise in this field and have been the market leader for SOLAS-compliant insulation for 45 years. Not only do the insulations excel in reducing fire risks, but they also meet exhaust gas standards, reduce noise, and provide perfect contact protection.

In addition to fire risk reduction, these factors are other important tmax insulation properties that are indispensable in increasing efficiency. Fire safety, of course, as a top priority.

Maximize fire protection – secure oil platform

At sea, it is usually impossible to escape quickly in the event of a fire, and outside help is not to be expected quickly. It is therefore important to provide fire protection for the oil platform.

This is what high-temperature insulation is for. To minimize the risk of fire and maximize fire protection.